Meeting summary

Kai Fischer, Scientific Director at IKV, welcomed the SAMPE Benelux attendees in Aachen on December 4th , 2024. We were lucky, as a double visit was planned: IKV and AZL! Our host, IKV or Institute for Plastics Processing was founded in 1950 as part of the Faculty of Mechanical Engineering at RWTH Aachen University. Research is driven at IKV by 300 sponsors from the full value chain of polymer processing and by 84 scientists that focus on 4 main research themes: additive manufacturing, circular economy, digitalization and lightweight technologies. Its leader, Prof. Christian Hopmann founded together with Prof. Christian Brecher (Chair for Machine Tools, WZL Aachen), the Aachen Center for Integrative Lightweight Production (AZL) in 2012. AZL is also located at RWTH Campus and carries out research on full-scale production lines for multi-material systems. Both IKV and AZL opened their lab doors for the visit of SAMPE BeNeLux members.

Before the visits, we kicked off with a lecture program. Kai Fischer highlighted first how polymers fit into many elements of the future hydrogen economy, from flow lines for electrolizers to matrix materials for carbon composite hydrogen vessels. Alexander Peitz of AZL then explained to us how AZL built unique equipment to enable mass production with thermoplastic composite tapes. Subsequently, Siebe Spronk of Syensqo demonstrated three ways to mechanically recycle thermoplastic composite waste into new parts and traded off the pros and cons of each method.

After the coffee slash networking break, Ali Shivaie Kojouri of VUB explained the challenges of and solutions for fracture mechanics testing of thick adhesive joints like present in wind turbines. Very different was the presentation by Gradel CEO Claude Maack who explained how their GRAM production concept allows to make very light composite structures that find their use in composite tooling, architecture, racing car seats or aircargo pallets.

Bernard Voss of ISOMATEX had the challenging job to keep everyone concentrated after the lunch break. He explained how his company develops basalt fibre grades, with specific sizings that offer low CO2 footprint, high impact resistance, high fatigue life or vibration dampening. The applications currently widen up from aerospace and sports to automotive. Finally, Alexander de Bruijn of KVE Daher explained the challenges of realizing an aircraft horizontal stabilizer torsion box in thermoplastic CF/PAEK composite. The box uses finally about 430 parts like flat or curved parts made by Automated Fibre Placement or thermoformed ribs. All of this is assembled together by about 400 welds!

Before the visits, SAMPE Benelux chairman Aart Willem van Vuure led the participants through the annual SAMPE Benelux member meeting. A few highlights were that our Benelux student Marion Cardous won the SAMPE Europe student contest, we welcomed three new committee members (Marie Hondekyn, Bram Jongbloed and Fabricio Brizon) and that we area about 170 members now and that we are looking forward to organize the SAMPE Europe Conference on October 6 and 7 in Amsterdam!

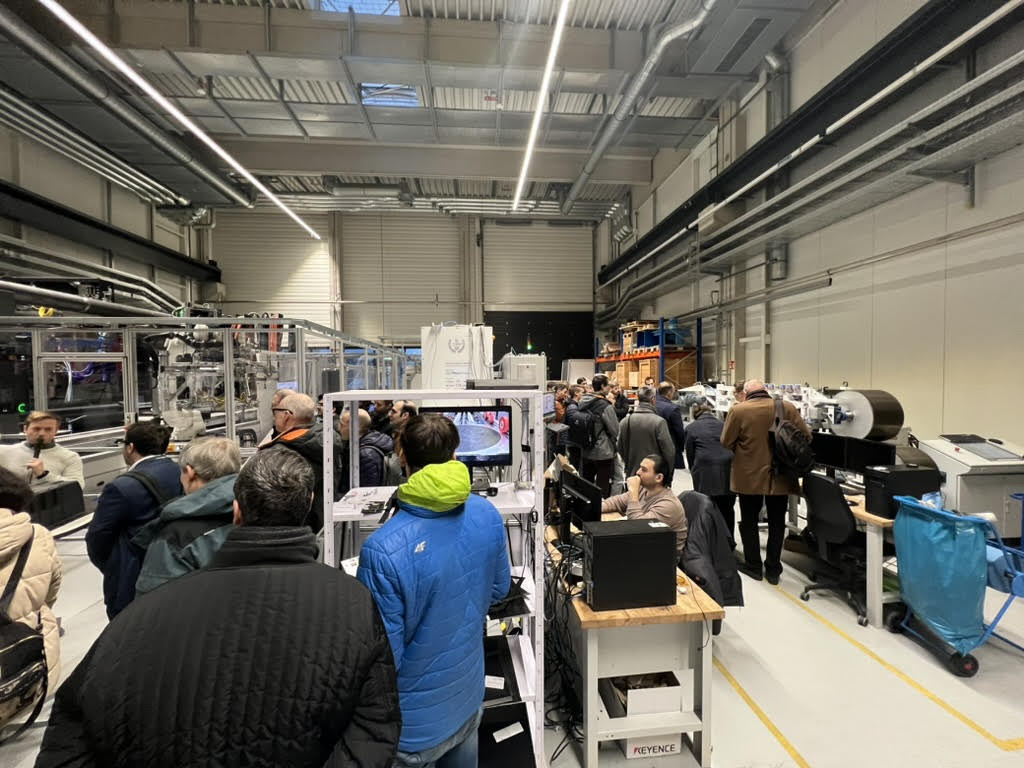

The IKV visit was impressive, showing a.o. a new robotic winding setup and a setup to integrate thermoplastic composite stiffeners in injection moulded parts. Yet the WOW moment came when AZL demonstrated its setups to lay-up and consolidate thermoplastic composite tapes as well as to injection mould automotive frunk shells with composite stiffening elements. Our SAMPE Benelux meeting outside Benelux was a true success!

Thank you to our host, the organizers, speakers and attendees for a great autumn meeting.